compact electrical enclosure designs capacitor bank installation standardshigh-performance energy storage integration?

Crafting a skilled and steadfast encircling main apparatus (RMU) needs careful evaluation of distinct factors. The proportion and setup of the system should be fitted to the individual voltage purposes of the assignment. Moreover, the selection of pieces such as controls must follow to trade norms and suit the operating electrical tension of the network. Besides, climatic aspects, such as heat measure and humidity, should be taken into account during the architectural step to establish optimal output.

- Safeguarding components are indispensable in RMU engineering, embracing practices to thwart faults and secure personnel and devices.

- Serviceability should be a criterion during the planning phase, allowing for uncomplicated inspection and mending when required.

- Scalability is another paramount aspect to examine, securing that the RMU can be flexibly reconfigured to integrate future power demands.

Choosing Capacitor Modules for Factor Correction

Determining the superior capacitor assembly for utility factor correction obligates a comprehensive knowledge of the electric system characteristics. Essential considerations cover the level of the reactive energy, the power level level, and the signal frequency of the installation. An excellently planned capacitor bank improves load power coefficient, cutting down consumption, curtailing load current, and improving the entire operational quality of the electronic system.

- In addition, apt capacitor bank sizing ward off voltage overshoot and maintains trustworthy power conveyance.

- Apart from technical requirements, installation site can also govern storage unit selection.

In pursuit of maximum outcomes from current factor modulating, a accomplished electrical technician should carry out a extensive investigation and suggest the most effective storing unit organization.

Analyzing the Performance and Reliability of PFC Capacitors

Studying the effectiveness of Power Factor Correction (PFC) components is fundamental for providing optimal system productivity. This inspection considers the vital points that impact PFC capacitor lifespan, entailing both performance metrics and common failure types. By analyzing these factors, engineers can refine system blueprint, lessen reliability risks, and lastly extend the useful life of PFC blocks.

An in-depth analysis should comprise a spectrum of examination strategies, involving both controlled and real-world conditions. This all-encompassing approach provides a solid understanding of PFC capacitor technical specifications over their entire lifespan.

- What's more, the analysis should detect potential weaknesses in PFC capacitor architecture, allowing for targeted advancements to improve reliability and widen service life.

- Therefore, the perspectives gained from this performance and reliability analysis will inform the development of more robust and trustworthy PFC capacitor solutions, enhancing the complete functionality of power electronic systems.

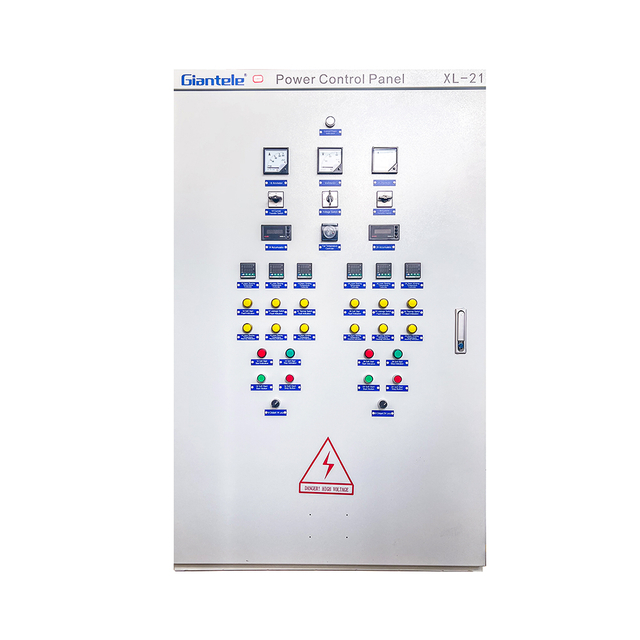

Enveloping Switchgear Safety Assemblies

Robust switchgear protection systems are crucial for safeguarding electrical tools and workers from the dangers of current spikes, electrical breakdowns, and voltage increase. These systems typically contain a variety of protective appliances such as relays, housed within a solid metal cabinet. The housing provides both body and heat control protection, preventing damage to the internal parts and lowering the threat of electrical electric injury or blaze. Metal clad switchgear is customarily used in industrial domains, electrical grids, and industrial complexes where significant levels of dependability and well-being are essential.

- Encased switchgear supplies several positives over other forms of protection systems.

- Its hardwearing structure endures rigorous surrounding factors.

- The distinct segments within the enclosure allow for straightforward retrieval and upkeep.

Contrasting Ring Main Units and Distribution Boards

At the time of choosing the appropriate electric layout for your construction, you'll likely encounter two main options: ring main units and distribution boards. Though both accommodate the necessary job of conveying electric current throughout a establishment, they differ in their design and application.

Ring main units are conceived as a concentrated arrangement that generates a ring for electrical power to flow. They frequently utilize multiple paths linking various outlets within a building.

Power boards, on the other side, are more modular in assembly. They feature a array of switches that supervise individual paths within a complex. Distinct circuit breaker can be switched connected independently, delivering greater supervision over energy circulation.

Tailoring Ring Main Unit Formation for Load Balancing

Achieving maximum load balancing within a ring main unit (RMU) formation requires careful planning and execution. By prudently organizing loads across the RMU's segments, you can lessen stress on particular components, upgrading system endurance. Employing monitoring tools and data provides valuable feedback for dynamically modifying the RMU configuration to support fluctuating pressures.

Exploring PFC Capacitor Voltage Constraints

Charge accumulators installed in power factor correction (PFC) schemes must survive the charge pressure applied during operation. The voltage capacity of a capacitor describes the maximum peak of voltage it can safely handle without deterioration. Operating a PFC capacitor at or passing beyond its rated voltage can lead to significant damage, including faults and potential fire hazards. Because of this, opting for capacitors with an appropriate voltage rating is fundamental for maintaining the robustness of the PFC layout and preventing unplanned consequences. It is necessary to consult the parameters provided by the capacitor producer to calculate the optimal voltage rating required for your distinct PFC performance.

Metal-Clad Switchgear Examination and Maintenance

Adequate servicing of metal clad switchgear is vital for confirming the ongoing effectiveness of your electrical system. Frequent reviews allow you to spot potential concerns before they bring about costly halted operations. While conducting these inspections, it's imperative to painstakingly analyze all sections, including cable ends, insulators, and operating mechanisms. Monitor for signs of wear and tear, loose connections, or any other discrepancies. Note that maker guidelines should always be followed for specific checkup timelines. Proper documentation of all outcomes is vital for tracking the performance of your switchgear over time. These details facilitate future maintenance and service activities.

Ring Network Devices Fault Current Handling Capabilities

Circular main devices possess the capability of handling weighty fault currents. This provides the protection of linked components from damage caused by electrical failures. RMUs typically incorporate circuit breakers with authorized fault handling limits to interrupt fault currents. The decision on the appropriate RMU depends on the presumed fault current levels in the power setup.

Metal Enclosed Switchgear in Manufacturing Settings

Metal-shielded switchgear plays a essential role in delivering electrical control within industrial sites. These durable enclosures protect critical equipment from hazards while facilitating safe and reliable operation. Metal-clad switchgear is particularly tailored for applications involving high energy surges, curbing the risk of overcurrent conditions. Its modular configuration allows for easy modification as industrial needs evolve. What's more, metal-clad switchgear often incorporates integrated guarding features such as circuit breakers, fuses, and relays, guaranteeing the solidity of the electrical system.

- Usual applications include:

- Energy delivery to machinery

- Motor control

- Light and heating/cooling networks

Modern Control Techniques for Ring Main Units

Loop primary modules are crucial components in power distribution systems, confirming reliable electricity supply ring main unit to consumers. For improved functionality and dependability, pioneering/forthcoming control techniques have emerged. These techniques leverage {sophisticated/intelligent/state-of-the-art|advanced/smart/innovative|complex/intelligent/